In the world of advanced atomizers—whether used for medical nebulization, industrial scenting, or electronic nicotine delivery systems (ENDS)—the battery is the unsung hero. It isn’t just a power source; it’s the engine that determines heat-up time, vapor consistency, and safety.

Choosing the right cell is critical for both performance and device longevity. Here’s a breakdown of what you need to know about applying battery technology to atomization.

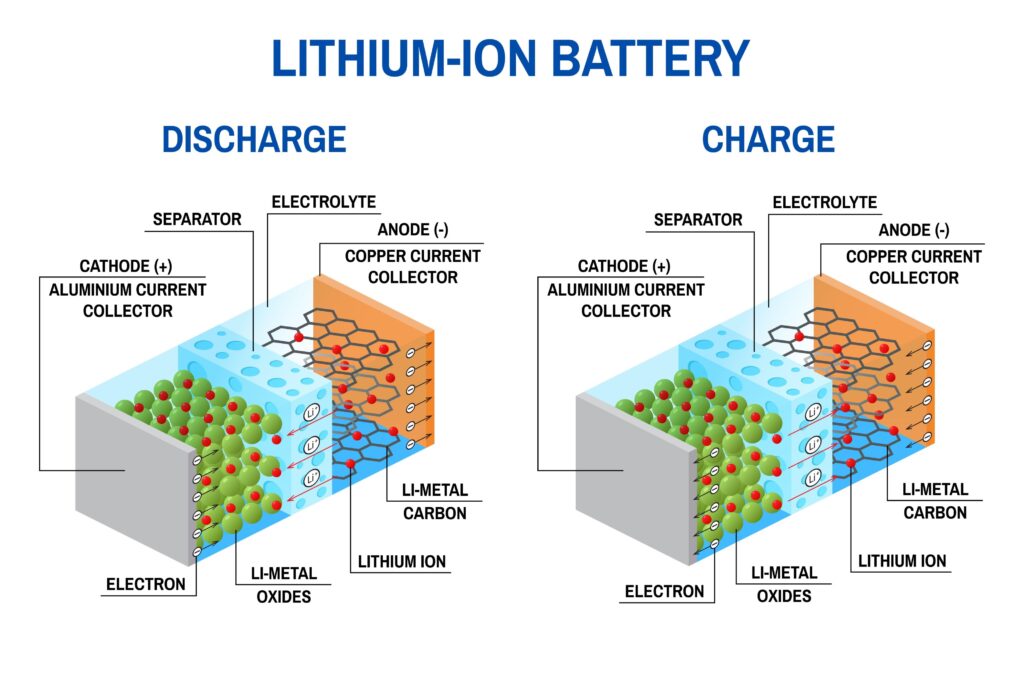

The Core Chemistry: Why Lithium-Ion?

Most high-performance atomizers rely on Lithium-ion (Li-ion) chemistry, specifically IMR (Lithium Manganese) or INR (Lithium Manganese Nickel) cells.

Safety: IMR/INR chemistries are more stable under high temperatures compared to older ICR (Lithium Cobalt) cells.

Discharge Rates: They can handle the high “drain” required to heat a coil rapidly.

Longevity: They offer a high energy density, allowing for a compact form factor that still lasts through a full day of use.

Key Technical Specifications

When selecting a battery for an atomizer application, three metrics matter most:

| Metric | Definition | Why it matters for Atomizers |

| Capacity (mAh) | How much energy the battery holds. | Determines how many “cycles” or “puffs” you get per charge. |

| Continuous Discharge Rating (CDR) | The maximum current (Amps) the battery can safely release. | Critical for safety. If the coil’s resistance is low, it draws more Amps. Exceeding CDR leads to venting. |

| Voltage (V) | The electrical potential (usually 3.7V nominal). | Influences the wattage output and how quickly the heating element reaches temperature. |

Understanding the Relationship:

The performance of an atomizer is governed by the relationship between voltage, current, and resistance. To calculate the current draw on your battery, use:

I=V/R

For example, if you are using a fully charged battery 4.2V with a 0.2Ω coil :

In this scenario, you must use a battery with a CDR of at least 25A to ensure a safety buffer.

Form Factors: 18650 vs. 21700

The industry has largely standardized around two sizes:

18650: The gold standard. Balanced, widely available, and fits in slim, ergonomic devices.

21700: The “new school” choice. Slightly larger, but offers significantly higher capacity (up to 5000mAh) and higher discharge rates, ideal for high-wattage industrial atomizers.

Best Practices for Battery Safety

Inspect the Wrap: The plastic sleeve (wrap) on the battery is its only insulator. If it’s torn, the battery can short-circuit against the device’s metal body. Never use a battery with a damaged wrap.

Use a Dedicated Charger: While many devices allow USB charging, an external smart charger ensures a more even, balanced charge and prevents overcharging.

Stay Within Limits: Always check your coil’s resistance. If you are building custom coils, use an Ohmmeter before firing.

Storage: Never carry loose batteries in your pocket. Always use a plastic case to prevent contact with keys or coins.

Looking Ahead: Solid-State and Beyond

As industrial battery applications evolve, we are seeing a shift toward Solid-State batteries. These promise even higher safety profiles (no liquid electrolyte) and faster charging times, which could revolutionize portable medical nebulizers in the coming years.

USB Rechargeable Lithium Battery

USB Rechargeable Lithium Battery